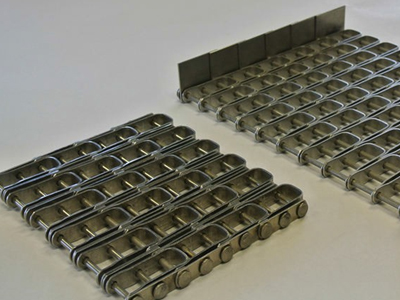

Flat wire Belting

Durable & Cost Effective

Flat wire belting, also named as honeycomb belting, is a well known traditional conveyor belt for most straight- running conveying applications. This hone comb belt features very large open area, high strength- to- weight ratio and flat carrying surface. All of these outstanding performances make it the most popular choice for baking, cooling, heating and packaging. Constructed from formed flat strips connected by cross rods,

flat wire belts have a wide variety of configurations to suit different requirements. For standard duty flat wire belting, 1" x 1" & 1/2" x 1" are frequently used, and other special specifications are available on request.

Flat wire conveyor belting has two edge styles - welded and clinched. Clinched edge is the first choice for standard duty flat wire belts, which can prevent mesh shrinkage on the rods. however, button welded edges are available.

Flat wire belting are manufactured by three common materials: low carbon galvanized steel (such as C 1015), high carbon steel (such as C 1050) and stainless steel T- 304 or T- 316.