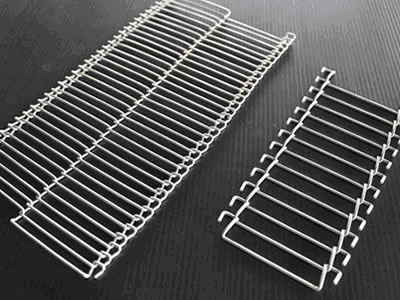

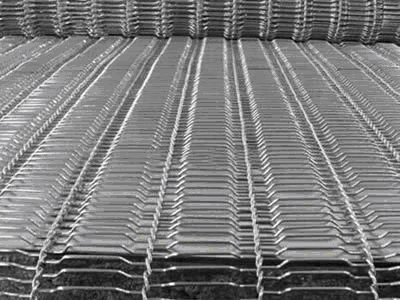

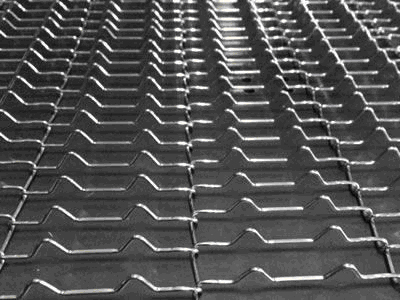

Wire Mesh Belt

Improved Efficiency

Wire mesh belts or wire link belts are ideal metal conveyor belts for light- to- medium transfers. Up to 86% proportion of open area provides maximum air- flow through and improve efficiency in cooling, heating, draining and drying performances. Smallest diameter end rolls and drive rolls mean that even the most dedicate products will be handled gently. At the same time, non- slip positive drive eliminates the possibility of tracking problems. Wire mesh belt uses USD A approved design and clean in place capacity make it much easier to keep the conveyor line hygienic. At the same time, this belt has numerous configurations for its great variety of wire diameters and different pitches.

Apart from straight- running wire mesh belt, radius mesh belt is provided for the conveying process around corners. Unique and tapered pitch, smallest inside turning radius and tightest level transfer make this curved wire mesh belt the perimeter choice for many corner process. Wire link conveyor belts not only suit for common conveying process, but also for special handling requirements. For example, some conveying process needs to keep the products aligned in rows, move product up steel

inclines or maintain product separation. Hence, flights throughout the belt length are manufactured. However, the number of rows of flights and spacing between each other are custom.